Introduction:

In the fast-paced environment of food production, ensuring the safety and quality of products is paramount. One area where there is a critical component of this process is the effective sealing of food depositor systems. Seals play a vital role in maintaining hygiene standards, preventing contamination, and safeguarding the integrity of the food being processed. Where food safety regulations are stringent, the importance of seals in food depositor systems cannot be overstated.

Preventing Contamination:

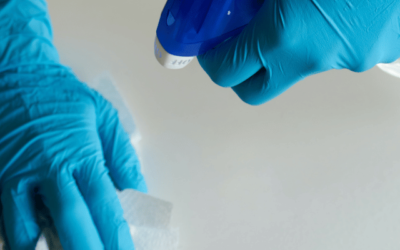

Seals act as a barrier between the depositor system and the environment, safeguarding against potential contaminants such as dust, dirt, and bacteria. By maintaining an airtight seal, they prevent any external elements from entering the system, thus reducing the risk of contamination. This is particularly crucial where strict food safety standards are enforced to protect consumer health.

Preserving Food Quality:

Food depositor systems handle a wide range of products, from ready meals to delicate confectioneries. Seals ensure that the depositor system remains a controlled environment, maintaining optimal conditions for product quality. They help retain the desired texture, flavor, and freshness throughout the production process.

Hygiene and Compliance:

Food safety regulations require adherence to rigorous hygiene standards. Seals contribute significantly to meeting these requirements by creating a sanitary barrier that prevents cross-contamination between different products. They are designed to be easy to clean and maintain, and are manufactured from food regulation compliant materials, ensuring the highest level of hygiene is upheld at all times.

Reliable Performance:

Seals in food depositor systems must withstand the demands of high-speed production lines. They are engineered to withstand pressure, temperature fluctuations, and repetitive movements without compromising their sealing capabilities. By providing a reliable, durable and consistent seal performance, they help maximize productivity while minimizing downtime for maintenance and repairs.

Conclusion:

Seals in food depositor systems are an essential component of the food production industry. They play a vital role in maintaining food safety, preventing contamination, preserving product quality and consistency, and ensuring compliance with strict regulations. By investing in high-quality seals and prioritizing their regular inspection and maintenance, food manufacturers can uphold the highest standards of hygiene, deliver safe and high-quality products, and maintain consumer trust in the food supply chain.